TRC’s Patented NAPL-Trapping Cap Technology Addresses Contaminants at the Sediment Source

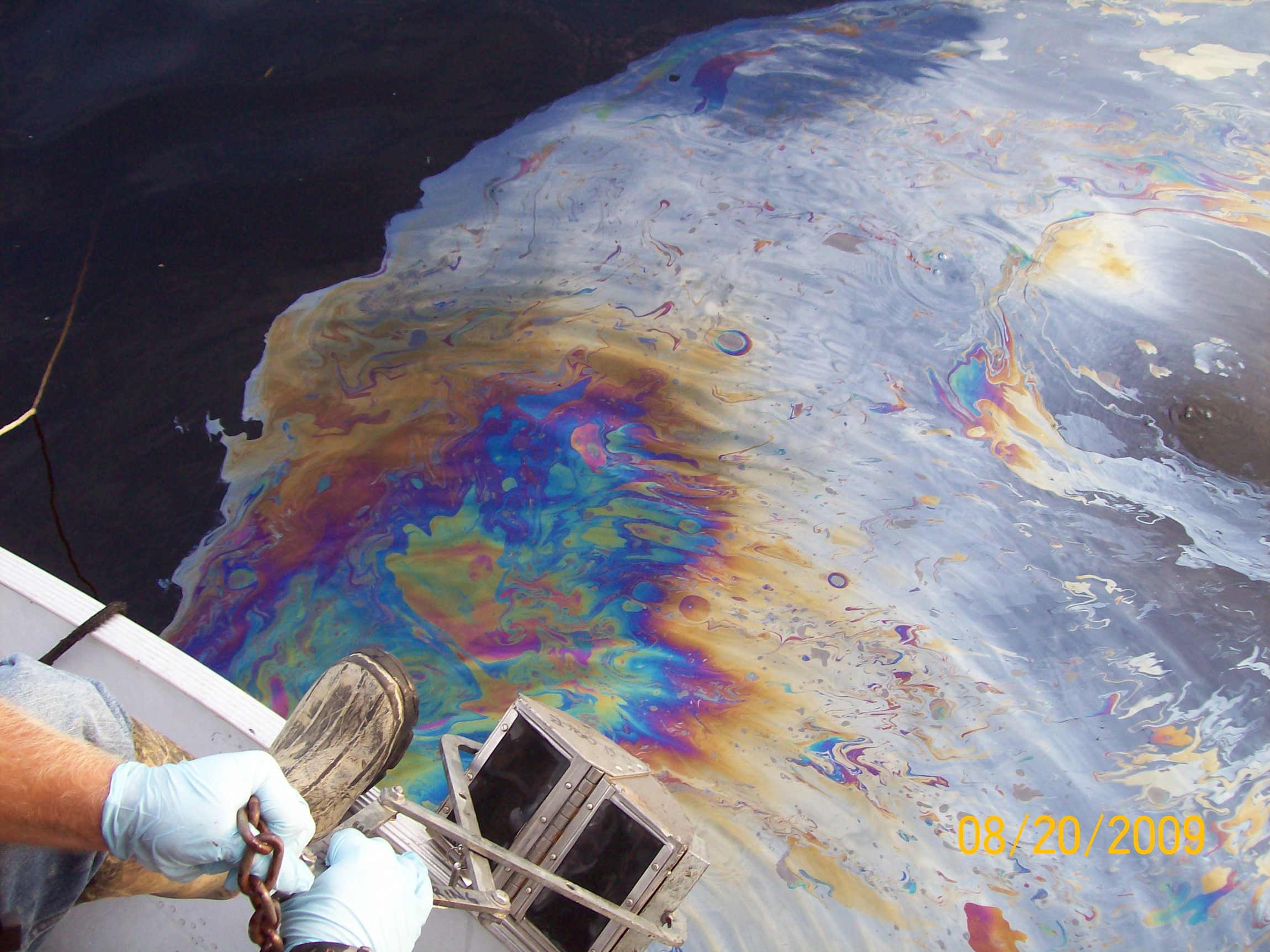

During the late 1800s through the mid-1900s, heavy industry and manufacturing sprang up along rivers and estuaries because of ready access to water, natural resources, transportation and waste disposal. Among the industries that thrived along water bodies were those that produced and refined oil, creosote and coal tar including refineries, bulk oil storage facilities, wood treating and manufactured gas plants (MGPs). Many of these facilities left behind a legacy of non-aqueous phase liquid (NAPL) e.g., oil and tar, in the upland soil and adjacent sediment. NAPLs can cause a toxic sheen on the water surface as they seep from the bank or as sediment is disturbed by gas bubbles (or ebullition).

Related Services

Dredging Solutions Have Drawbacks

Traditional solutions for remediating sediment contamination involve dredging to remove the contaminant mass in sediment, but they are not 100 percent effective in removing NAPL in sediment. Even one residual lens of NAPL left in the sediment can cause sheens to form for many years after the dredging has been completed. The sheens that are formed contain hundreds of thousands of parts per million of potentially cancer-causing chemicals and present a clear threat to human and ecological receptors.

Traditional Sediment Caps Do Not Target Ebullition

To address the potential for ongoing migration of residual impacts, sediment caps are often placed over areas that have already been dredged. However, traditional sand caps do not prevent ebullition-driven migration of coal tar NAPL through the cap and into the overlying water column. Similarly, amended caps serve only to delay future release of NAPL and consequent sheen formation. And because impermeable caps do not stop continuing bacterial biodegradation and gas formation, gas bubbles can build up under impermeable caps and either cause eventual uplift, resulting in a physical breach of the cap, or they migrate around the cap into the water column. A NAPL-trapping cap design offers an alternative solution to prevent NAPL migration and impact to water quality.

Engineering A New Approach: TRC’s NAPL Trapping Cap

To address all the shortcomings of traditional methods, scientists and engineers at TRC engineered and patented (US 8,419,314 and US8,651,768) an approach that caps and controls contaminant release by managing the ebullition. The innovative cap creates a seal over the NAPL-contaminated area of the river or canal bed, which is combined with a gas venting layer to allow capture and release of naturally occurring gas bubbles emanating from the sediments. The cap allows the ebullition to occur, but the NAPL-carrying bubble mixture is channeled by the impermeable containment layer to flow through the transmission layer toward the accumulation zone. At this point the bubbles will pop and the NAPL is trapped within the cap. In most cases, the NAPL is then immobilized in a relatively inert condition. However, NAPL extraction processes can be employed to remove the accumulated NAPL, if required. NAPL-trapping caps have been installed in widely different settings, including Ann Arbor, Michigan; Bangor, Maine; Chesapeake, Virginia; Tulsa, Oklahoma; Brooklyn, New York; and Ripon, Wisconsin.

The NAPL-trapping cap can also be designed to integrate with the upland remediation. This is a key feature because many NAPL sites exhibit pooled upland NAPL impacts that represent potentially continuing migration toward a waterbody. A NAPL-trapping sediment cap that addresses both in-water NAPL and potentially migrating upland residual can be a far more feasible and cost-effective remedy than attempts to hydraulically cut off upland NAPL. The owners of these sites tout the NAPL-trapping cap solution for a variety of reasons: It is more effective in controlling the release of NAPL than dredging and while other cap designs have finite lifespans this one is permanent; and when amortized over its lifetime, it is more cost effective.

Protecting the Environment for the Future

In the 19th and 20th centuries, industry powered the United States into great growth, long before we understood the consequences of discharging petroleum and coal tar residuals into waterbodies. Pooled NAPL in soil and sediment has proven to be a more recalcitrant contaminant issue than at first realized, but American ingenuity has devised an elegant remediation solution that is both certain and permanent. NAPL trapping cap designs are suited to a range of settings. Utilizing sediment caps for the remediation of waters has benefits that extend past healing the environment. Bodies of water such as rivers and lakes that were previously contaminated can now be used by people for recreational activities like fishing, boating and swimming and adjacent properties can be beneficially redeveloped. The wildlife that living in and around these formerly contaminated sites can once again thrive along clean rivers and lakes. Thanks to new sediment caps, both people and animals can enjoy a safer and healthier life.