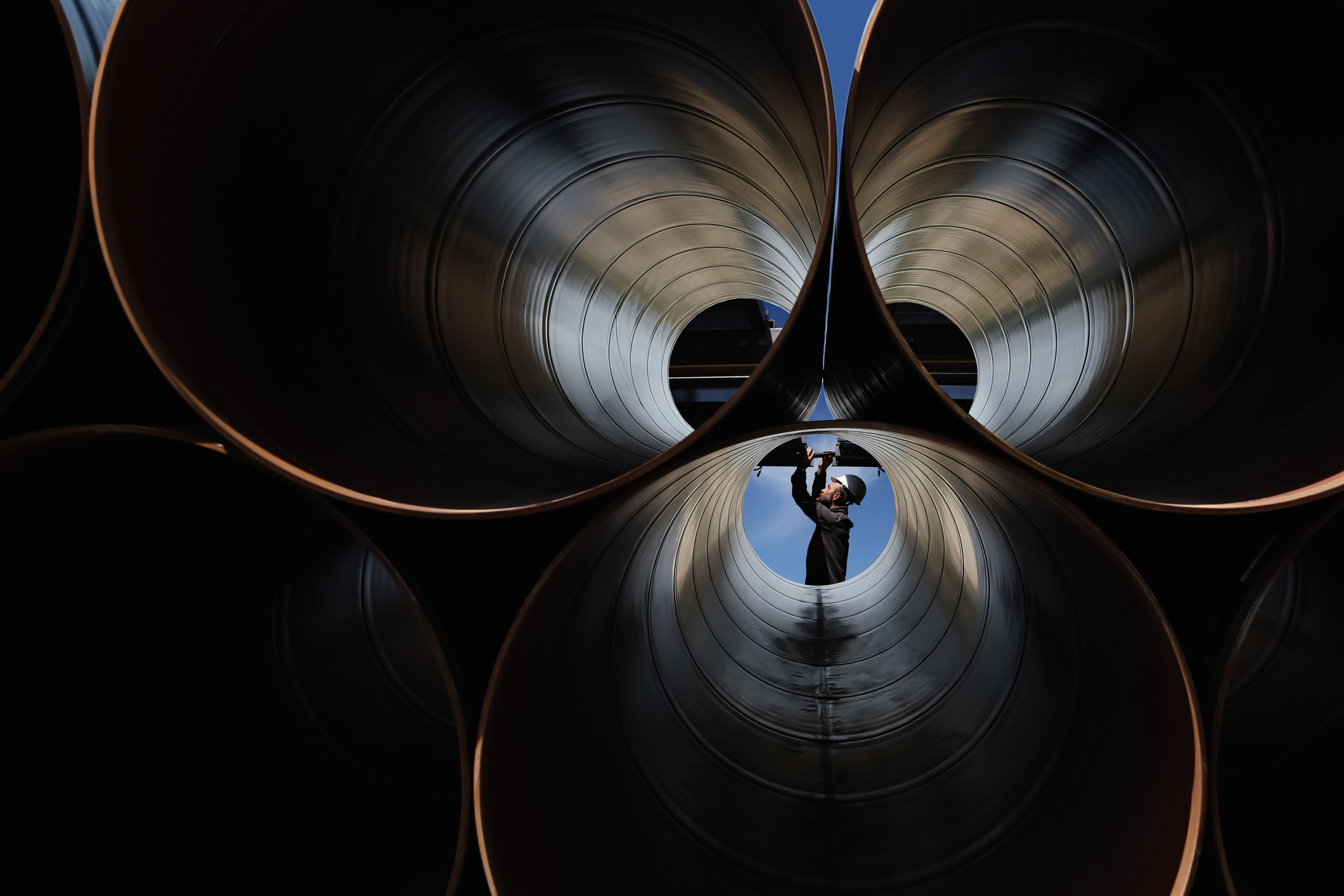

TRC works with transportation authorities, construction teams and materials manufacturers to evaluate commercial and private facilities, complex structures, new construction, highways, roads, bridges, wastewater processing facilities and more. Our inspections make sure these structures are safe, durable and compliant with design standards and specifications.

Real-Time Data Sync. One-Click Reporting.

Conventional fabrication inspection practices aggregate electronic and paper forms and use manual data entry for regulatory reporting. TRC’s Inspection Insights generates complete reports at the click of a button, cutting months off the process.

Our Inspection Insights data solution collects cloud-based data that provides real-time insight into inspection procedures and outcomes.