Quality Management, Engineering and Regulatory Support

Although PFAS were once useful additives in the electroplating industry, factories that used these chemicals are now potentially liable for managing impacted surface water and groundwater around their facilities.

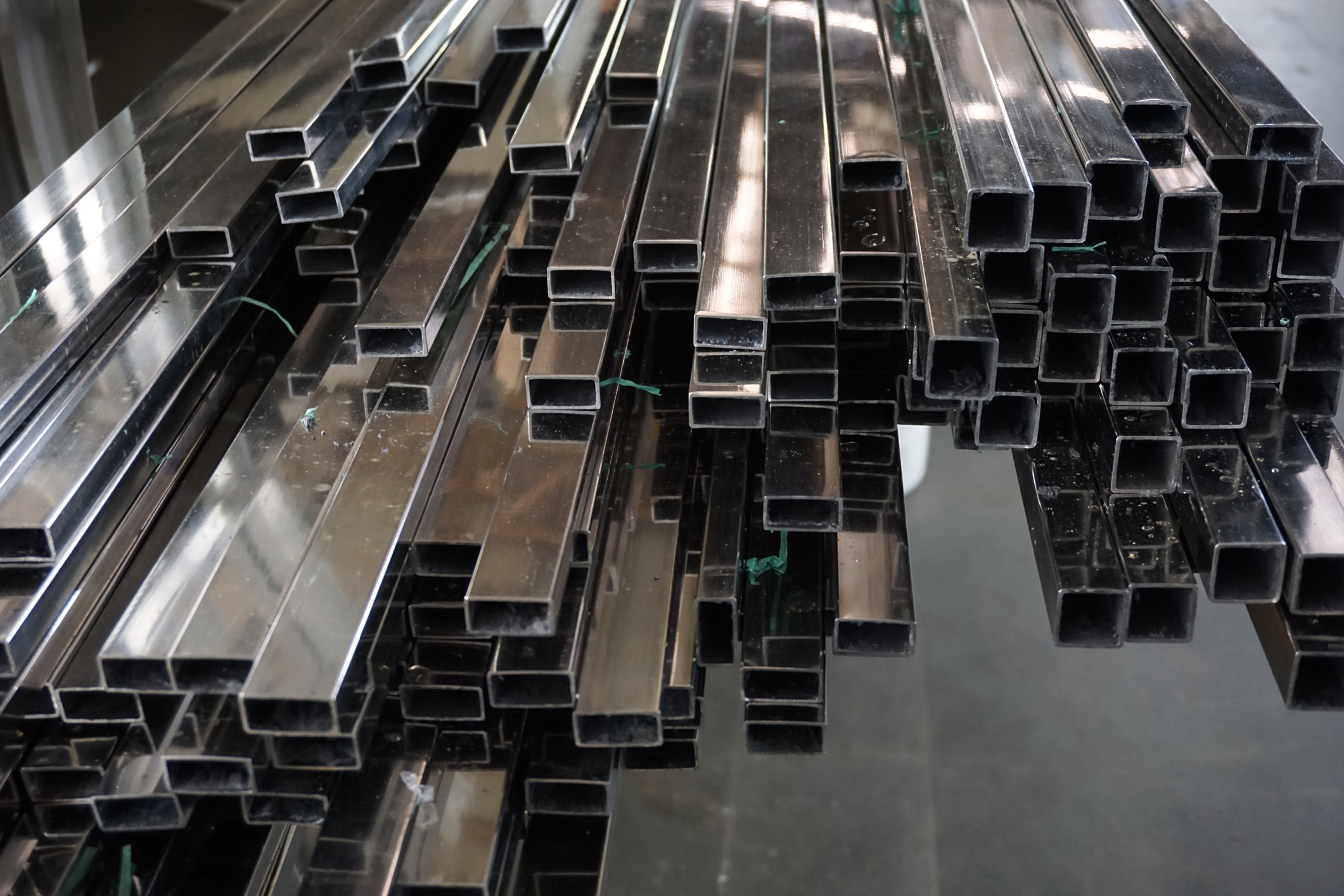

Since the 1950s, PFAS have been used to control hazardous chromic acid mist and improve the stability and quality of copper, nickel and tin electroplate baths. Traces of the chemicals, including PFOS, are now showing up in groundwater sources.

While no federal regulations for PFAS currently exist, states have already initiated testing of surface water and groundwater around plating facilities with reported releases or where drinking water has been found to contain PFAS.

As more data emerges about PFAS chemicals, regulations are on the increase. Organizations that use these chemicals can act now to identify and resolve potential historical liabilities that could result from direct or indirect sources of PFAS released into the environment. Proactive response strategies may include:

- Reviewing records to understand the types of chemicals used in the metal plating processes

- Carrying out a wastewater sampling and analysis program

Resolve Your PFAS Liabilities With TRC

TRC’s nationwide PFAS specialists and environmental engineers have carried out sampling and analysis programs for metal plating facilities that have confirmed and unconfirmed the use of PFAS-based surfactants and wetting agents.

Identifying PFAS is complex and different from other environmental contaminants. Our PFAS specialists plan and manage the entire process to ensure the sampling is done right and the results are representative before clients spend money to install treatment, containment or disposal systems.

Adapt to

Change

Partner With TRC’s Tested Practitioners

Gain Peace of Mind – Contact Us Today

TRC’s nationwide team of PFAS experts and environmental engineers offers comprehensive solutions tailored to the unique challenges faced by the electroplating industry. From record reviews to advanced sampling and analysis programs, we provide the expertise needed to identify, assess, and mitigate PFAS-related risks. Take control of your environmental responsibilities and safeguard your business. Contact TRC today to develop a strategic PFAS management plan that protects your facility, your reputation and your bottom line.